Brief introduction of Lignite dryer machine

Our factory is the professional manufacturer of Lignite dryer machine in China, we can provide you the rotary dryer with the high cost performance. The Lignite rotary dryer can dewater and dry for that watery material, and it can change the moister as 13% below by dewatering. With latest technology, Lignite charcoal dryer machine can increase the burning efficiency, make the best of the carbon resource, reduce the density of waste, achieve the saving energy & reducing waste and the safety & protection. Based on the traditional structure of the rotary dryer, this new type of Lignite rotary dryer can not only break materials, but also improve the thermal efficiency of drying machine. It can even deal with crumb, high moisture sticky materials, paste material and liquid materials. And it is applicable to the chemical industry, brewing, pharmaceutical industry, etc.

Performance characteristics of Lignite dryer machine

1. Large capacity, continuous and stable operation;

2.Rotary speed and scattering device speed can be adjusted, and can meet the requirements of different materials;

3. Low consumption and energy saving; the water in finished products are under 30%.

4. Dependable structure and good Manufacturing to guarantee it fine with long-time operation.

5. It is widely used for drying slag limestone, coal powder, slag, clay, etc, and it can be used to dry grain.

6. With the recycle burning device, Lantian Lignite rotary dryer save coal, reduce the coal powder content of finished product.

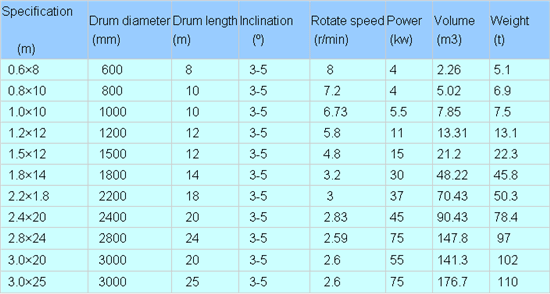

Technical parameter of Lignite dryer machine

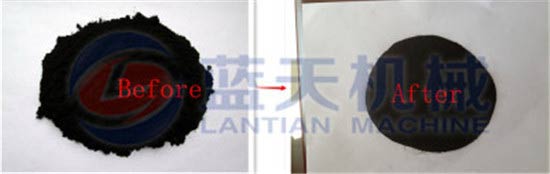

Compared before and after drying

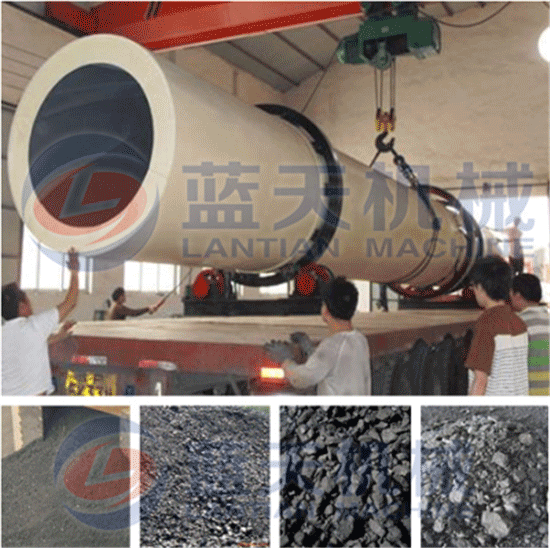

Working principle of Lignite dryer machine

The wet materials are conveyed to the hopper through the belt conveyor or bucket elevator, and then enter into the feed end through the hopper charger and the feeding pipe in sequence. The inclination of the feeding pipe must be greater than the natural inclination of materials in order to make the materials flow into the dryer smoothly. The materials enter from the higher end, and the heat carrier enters from the lower ender; the two contact each other from opposite directions, but there are also circumstances that the heat carrier flows into the dryer body together with the material.

The case

Customers Visiting Our Factory

Packaging and shipping

Our certifications

Our Services

1, Accept the customer's ask, confirm the scale, provide the purchase plan according to the customer's need

2, Provide the related technology documents to customers

3, Test the equipment for customers on free

4, Provide genuine part in time

5, Accept the Technical Advisory ,provide the technique in diagnosis for 24 hours

Company information

Located in Gongyi, Zhengzhou province in China, Lantian machinery is a professional drying equipment manufacturer specialized in manufacturing all kinds of drying equipment such as Lignite dryers, Lignite charcoal dryer machine ,rotary dryers and dust collectors, which is widely used in chemical and food factories etc. Our company sticks to honesty, quality, and the survival of the enterprise purpose, won several municipal contract and keep credibility, trustworthy products and so on the title, the product all over at home and abroad, by the customer consistent high praise. Welcome friends from all walks of life colleague to visit our company guidance, seek common development.

NEXT:Fly ash dryer